Vogamakina Transfer type powder coating line other conveyor

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Turkey

Turkey

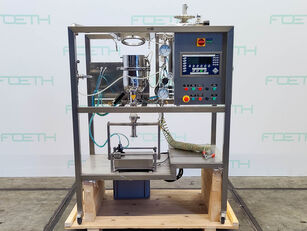

Transfer type conveyorised powder coating or wet painting plants consist of a combination of conveyor rails and trolleys. These systems are combined with plant elements such as paint oven, paint booth, washing booth or sandblasting booth and designed by us according to the dimensions of the customer's workshop.

The workpieces are processed by hanging on the beams moving horizontally on the conveyor rail and passing through the paint booth, oven and other parts of the plant by manual pulling or automatic movement of the beams.

In transfer type powder or wet paint lines, the products are manually loaded onto the conveyor and manually unloaded from the conveyor after cooling. Therefore, the labour costs required for intermediate operations such as unloading and re-hanging are reduced. Since the operation and labour costs are reduced, the cost and time savings provide a great gain in comparison with manual plants.

Transfer type powder coating systems can be designed as fully manual, semi-automatic or fully automatic. In these plants, workpieces can be painted automatically while passing through the paint booth, and the products can be automatically taken into the oven after painting. The system is fully suitable for automation and can also be designed as fully PLC controlled.

Transfer type paint plants can be designed by us in workshops with complex dimensions and geometry and can work effectively thanks to its compact design feature.

During the project phase, our design office will make the most effective facility plan according to your workpieces and workshop dimensions and present it to you.