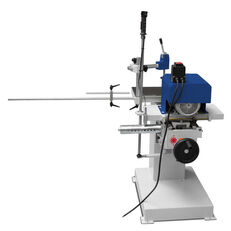

Biesse SKIPPER 100 wood boring machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

Additional equipment

Roller infeed table

Upper pressure table

Lower pressure table

Upper and lower working units

Belt outfeed conveyor (right side)

Electronic thickness control

Automatic central lubrication

CNC control system: XP 600 with Soft CN

Safety system

Machine Benefits

Qualitative Machine Benefits

Condition: well maintained and regularly serviced

Technical Machine Benefits

Electrospindle type: hsk

Injection unit power: 3. 5 kw

Workpiece length: 90–3000 mm

Workpiece width: 70–1000 mm

Workpiece thickness: 8–60 mm

Extra Information

Dimensions of Machine (LxWxH)

Working Range X Axis:

Vertical Drilling: 0–3000 mm

Horizontal Drilling in X and Y: 0–3000 mm

Continuous Milling: 0–2500 mm

Partial Milling: 0–3000 mm

Continuous Grooving with Saw: 0–2500 mm

Partial Grooving with Saw: 0–3000 mm

Working Range Y Axis:

Vertical Drilling: 0–1000 mm

Vertical Drilling with System 32: 32–1000 mm

Horizontal Drilling in X: 0–1000 mm

Horizontal Drilling in Y: 90–1000 mm

Milling: 0–950 mm

Grooving with Saw: 112–1000 mm

Working Range Z Axis:

Material Thickness: 0–60 mm

Tools

Total Spindles: 78

Top Unit: 39

Bottom Unit: 39

Vertical Spindles:

Total: 29

In X Direction: 19

In Y Direction: 10

Horizontal Spindles in X:

Double Output: 4

Independent Horizontal Spindles:

In X Direction: 2

In Y Direction: 2

application type: CNC Wood Machining

Location: Poland

machine type: CNC Processing Center

Number of Axes: 3