New Iberdrill Falken AZ 34 drilling machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

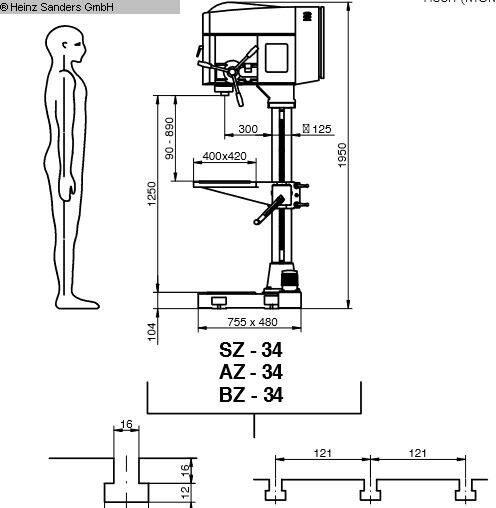

throat 300 mm

bore stroke 150 mm

bore capacity in cast iron (diameter) 40 mm

thread capacity M 27

spindle taper MT 4

spindle speeds: Stufenlos 100 - 2000 U/min

column diameter 125 mm

automatic feeds 3 / 0,1 - 0,2 - 1,3

table: 400 x 420 mm

Drive Keilriemen

total power requirement 3 kW

weight of the machine ca. 360 kg

dimensions of the machine ca. 2,3 x 0,6x 1,1 m

bore capacity in steel (diameter) 34 mm

throat 300 mm

bore stroke 150 mm

bore capacity in cast iron (diameter) 40 mm

thread capacity M 27

spindle taper MT 4

spindle speeds: Stufenlos 100 - 2000 U/min

column diameter 125 mm

automatic feeds 3 / 0,1 - 0,2 - 1,3

table: 400 x 420 mm

Drive Keilriemen

total power requirement 3 kW

weight of the machine ca. 360 kg

- Drilling machine of circular column feed automaticmechanical

- Drive by electronic wide V-belt

- Spindle taper: CM 4

- Stepless speed adjustment with frequency converter

- Potentiometer for speed adjustment

- digital speed display

- Automatic feed reversal when threading

- Scale with adjustable drilling depth - automatic tool ejector

- Push button for EMERGENCY STOP switch for right/left rotation

- Electronic control integrated in the drill head - integrated coolant system

- Machine light - height-adjustable chip protection disc with micro switch

- fixed table

- CE marking

The data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

Ausladung 300 mm

Bohrhub 150 mm

Bohrleistung in Guß (Durchmesser) 40 mm

Gewindeschneidleistung M 27

Spindelaufnahme MK 4

Spindeldrehzahlen: Stufenlos 100 - 2000 U/min

Säulendurchmesser 125 mm

Vorschub automatisch 3 / 0,1 - 0,2 - 1,3

Tisch: 400 x 420 mm

Antrieb Keilriemen

Gesamtleistungsbedarf 3 kW

Maschinengewicht ca. 360 kg

Raumbedarf ca. 2,3 x 0,6x 1,1 m

Bohrleistung in Stahl (Durchmesser) 34 mm

Ausladung 300 mm

Bohrhub 150 mm

Bohrleistung in Guß (Durchmesser) 40 mm

Gewindeschneidleistung M 27

Spindelaufnahme MK 4

Spindeldrehzahlen: Stufenlos 100 - 2000 U/min

Säulendurchmesser 125 mm

Vorschub automatisch 3 / 0,1 - 0,2 - 1,3

Tisch: 400 x 420 mm

Antrieb Keilriemen

Gesamtleistungsbedarf 3 kW

Maschinengewicht ca. 360 kg

- Bohrmaschine des rundsäule Vorschubs automatischmechanisch

- Antrieb durch elektronischerbreitkeilriemen

- Spindelkegel: CM 4

- stufenlose Drehzahlverstellung mit Frequenzumrichter

- Potentiometer zur Drehzahleinstellung

- digitale Drehzahlanzeige

- automatische Vorschubsumkehr beim Gewindeschneiden

- Skala mit einstellbarer Bohrtiefe- automatischer Werkzeugauswerfer

- Drucktaste für NOTSTOP- Schalter für Rechts/Links-Lauf

- Elektrosteuerung in Bohrkopf integriert- integrierte Kühlmitteleinrichtung

- Maschinenleuchte- höhenverstellbare Späneschutzscheibe mit Mikroschalter

- fester Tisch

- CE-Kennzeichnung